The production facilities cover all the required fabrication machinery like Bending Rollers, latest Automatic Plasma Welding Machines, Orbital Welding Machines, Plasma Cutting Machines, Lathes, Drilling Machines, Auto Surface Finish Machines, Grinding and Automatic Polishing Machinery, Boroscopy, Electro-Polishing for Vessels and Piping.

The Quality Control Department is equipped with all In-house facilities for accessing welding quality, thicknesses, surface finishes, Hydro/Pneumatic/Vacuum Testing, Agitator Running Performance, Vessel Calibration etc. with latest instruments.

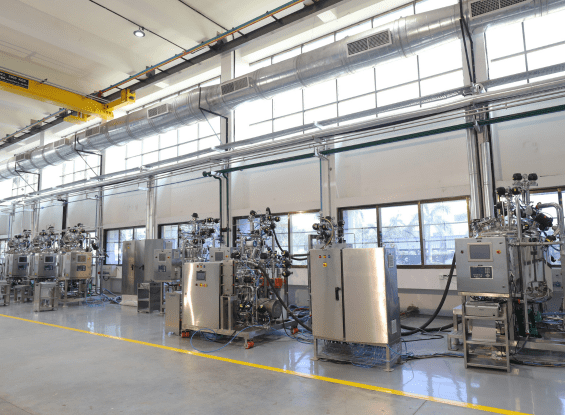

Pharamatech Process Equipment’s production process competencies and range of products cover the different production ‘states’ starting with liquid forms (including aseptic processing), semi-solids and solid components (API and Fine Chemicals). Pharmatech Process equipments and turn-key systems are constantly designed and up-graded as per International regulations and the standards followed in the Pharmaceutical, Biotechnology and Cosmetic Industries.

Modern and extensive range of products, process competence, dynamic organization, global presence and available resources prove Pharmatech Process “The Ideal Partner For Advanced Processing Solutions” in Pharmaceuticals, Bio-pharmaceutical and Cosmetic industries all over the world.

The production department is headed by well-qualified and long experienced General Manager (Production) having a team of managers & supervisory staff of qualified engineers manage, the work force of about 100 people including skilled welders and expert of surface finish and polishing team.

As per the Quality Assurance Plan, each and every vessels are passed through stringent procedure of inspection right from the receiving material testing to running trials as per DQ/FAT formalities laid by current GMP standard. Dispatch of each vessel follows by technical documents carrying DQ/IQ/OQ and PQ with all necessary test certificates and “As – Built” drawings.

Pharmatech Process is considered to be the excellent compared to International standard. So far, the company has served all the major Pharmaceutical, Bulk Drug, Food, Cosmetic, Biotech and Beverage Industries and also has credit of exporting to Middle East, South-East Asia, Europe, Latin America, and Africa.